Paper

converters are the people in the middle of everything! They receive paper over

which they have little control and they produce converted products and supply

many customers that have no way to analyze their products or have facilities

that may not be able to handle variances in moisture. Essentially paper products

are big sponges that readily absorb moisture or dry out depending upon the

environment (the supplier’s mill, intermediary warehousing, trucking and

finally their own warehouses). If just one step in this chain is not properly

temperature and humidity controlled the moisture content can vary quite a lot.

As seasons change incoming paper can go from too dry to too moist. Converting

equipment is fine tuned for paper types and basis weights and change in

moisture. Moist paper can get thicker jamming machines. Dry paper can become

friable and break. Dryer or moisture paper may affect friction and the

measuring systems used. Then we get to the converted paper you supply. If going

to printers increased moisture can affect the absorption of inks leading to

poor absorption and colours or to bleeding or excess ink usage and you get the

blame whether it’s your fault or not.

Concreters more than any more need to monitor incoming and outgoing paper. Incoming to control costs and reduce waste in your own production processes and on outgoing products to protect yourselves. You might take the attitude it’s not yours after it leaves your dock, but your clients see it differently and being able to test product before shipping protects you from false claims of substandard products. If you can test at your shipping dock and then get complaints and test at the client’s facility and find moisture is 10-20% higher.

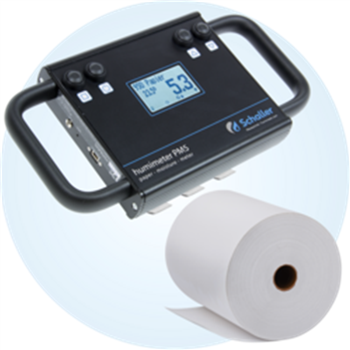

Suggested Products:

| Product Number | Description |

| HM-14300 | MF-P-HTD Paper Moisture Sensor |

| HM-14560 | MF-S-HTD Paper Moisture Sensor |

| HM-13800 | PM5 Humimeter - Paper Moisture Meter |

| HM-13300 | RP6 Humimeter - Moisture Meter for Recycling Paper |